Nhanganyaya:

Battery spot welding machinesmaturusi akakosha mukugadzira uye kusangana kwemabhatiri mapaketi, kunyanya mumotokari yemagetsi uye zvikamu zvesimba rinogoneka. Kunzwisisa misimboti yavo yekushanda uye kushandiswa kwakakodzera kunogona kuwedzera zvakanyanya kushanda uye kunaka kwekusangana kwebhatiri.

Battery Spot Welding Machine Working Principle

Battery spot welding inzira inobatanidza simbi mbiri kana kupfuura pamwechete nekuisa kupisa nekumanikidza. Izvi zvinowanikwa kuburikidza nekushandiswa kwemagetsi emagetsi anoyerera pakati pezvishandiso. Zvinhu zvakakosha zve anzvimbo welding muchinazvinosanganisira:

1. Electrodes: Aya anowanzo gadzirwa nemhangura uye anoshandiswa kuitisa magetsi kune izvo zviri kusungirirwa. Dhizaini yema electrode inogona kusiyana zvichienderana neiyo chaiyo application uye rudzi rwesimbi dziri kubatanidzwa.

2. Transformer: The transformer inoderedza high voltage kubva kune simba remagetsi kusvika kune yakaderera voltage yakakodzera kune welding process paunenge uchiwedzera ikozvino.

3. Kudzora Sistimu: Michina yemazuva ano welding michina ine microcontrollers inobvumira kunyatso kudzora pamusoro peiyo welding paramita, seyazvino, nguva, uye kumanikidza.

Maitiro acho anotanga kana ma electrode akaiswa panzvimbo inoiswa welded. Ikozvino inozopfuura nepakati pema electrode, ichigadzira kupisa nekuda kwekupikisa kwemagetsi pakusangana kwesimbi. Kupisa uku kunokwidza tembiricha kusvika pakunyungudika kwezvinhu, zvichiita kuti zvibatane pamwechete. Kudzvinyirirwa kunoshandiswa nema electrode kunobatsira kuvimbisa chisungo chakasimba nekuderedza kuumbwa kwemaokisi pamubatanidzwa.

Mushure menguva pfupi yekutonhora, iyo welded joint inosimbisa, zvichikonzera kubatana kwakasimba kwemichina. Muitiro wacho wose unowanzo kurumidza zvikuru, uchitora chikamu chiduku chesekondi.

Battery Spot Welding Machine Usage Methods

- Kugadzirira

Usati washandisa abhatiri nzvimbo welding muchina, zvakakosha kugadzirira nzvimbo yekushanda uye zvinhu:

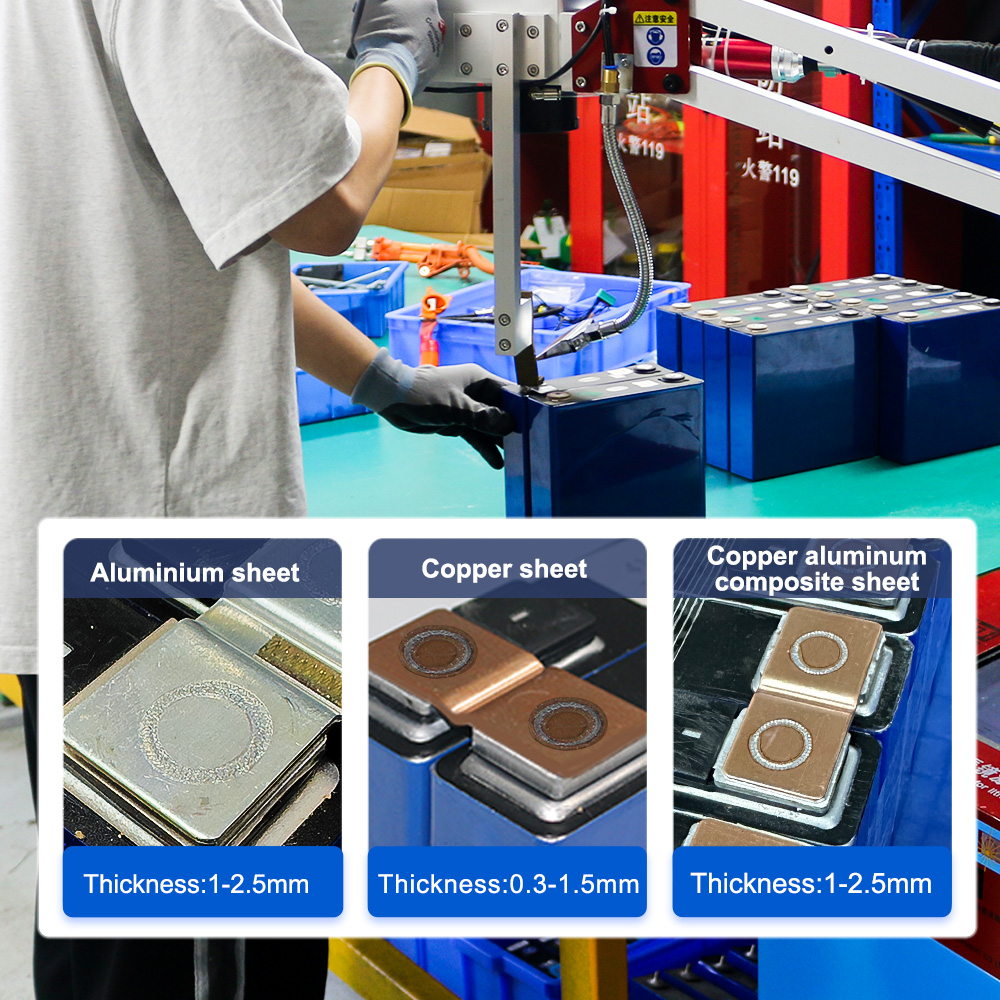

1. Kusarudzwa kwezvinhu: Ita shuwa kuti simbi dziri kusungirirwa dzinoenderana. Zvishandiso zvakajairika zvekubatanidza bhatiri zvinosanganisira nickel-plated simbi uye aluminium.

2. Kucheneswa kwePamusoro: Chenesa nzvimbo dzinofanira kuiswa weld kuti ubvise chero zvinosvibisa, zvakaita segirisi, tsvina, kana oxidation. Izvi zvinogona kuitwa uchishandisa solvents kana abrasive zvinhu.

3. Equipment Setup: Kunyatsogadzirisa muchina maererano nemirairo yemugadziri. Izvi zvinosanganisira kugadzirisa ma electrode uye kuve nechokwadi chekuti zvese zvekuchengetedza zviri kushanda.

- Spot Welding MachineWelding Process

1. Positioning: Isa masero ebhatiri uye mitsara yekubatanidza munzvimbo yakarurama pakati pemagetsi. Ita shuwa kuti dzakarongeka kudzivirira chero kusarongeka panguva yewelding process.

2. Kuisa Parameters: Gadzirisa mapeji ekushongedza pane hurongwa hwekutonga, kusanganisira ikozvino kusimba, nguva yekuputika, uye kudzvinyirira. Aya marongero anogona kusiyana zvichienderana nemidziyo uye ukobvu huri kusungirirwa.

3. Welding: Activate muchina kutanga welding process. Chengetedza kushanda kuti uone kuti ma electrode anochengetedza kubatwa kwakakodzera uye kuti ikozvino inoyerera nemazvo.

4. Kuongorora: Mushure mekugadzira, tarisa maziso kune chero kukanganisa, zvakadai sekusangana kusina kukwana kana spatter yakawandisa. Mamwe maapplication angangoda kumwe kuyedzwa kwekuenderera kwemagetsi kana simba remagetsi.

Mifungo Yekuchengetedza

Kushanda nemichina weldinginogona kuunza dzimwe njodzi. Nguva dzose tevera mitemo yekuchengetedza:

1. Dziviriro Yegiya: Pfeka midziyo yekuzvidzivirira nayo yakakodzera (PPE), kusanganisira magirovhosi, magirazi ekudzivirira, uye maapuroni kudzivirira pfarivari uye kupisa.

2. Ventilation: Iva nechokwadi chekuti nzvimbo yekushandira inofefeterwa zvakanaka kudzivirira kufemera chero utsi hunogadzirwa panguva yewelding process.

3. Emergency Procedures: Zvijairirane nemaitirwo ekuvhara kwechimbichimbi uye uve nechokwadi chekuti muchina wacho wasvika pakumira kwechimbichimbi.

Mhedziso

Battery spot welding machinesita basa rakakosha mukusangana kunoshanda kwemabhatiri mapaketi. Kunzwisisa misimboti yavo yekushanda uye kutevedzera nzira dzekushandisa dzakafanira kunogona kutungamira kune emhando yepamusoro welds uye kuwedzera chibereko. Nekukoshesa kuchengetedza nekugadzirira, vashandisi vanogona kushandisa michina iyi nemazvo mumashandisirwo akasiyana siyana, zvichibatsira mukufambisira mberi kwetekinoroji yekuchengetedza simba.

Kana iwe uine pfungwa yekuunganidza bhatiri iwe pachako, kana iwe uchitsvaga yakakwirira-chaiyo nzvimbo welder yebhatiri welder yako, ipapo nzvimbo welder kubva kuHeltec Energy yakakodzera kufunga kwako.

Kana uine chero mibvunzo kana uchida kudzidza zvakawanda, ndapota usazezasvika kwatiri.

Chikumbiro cheQuotesheni:

Jacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Nguva yekutumira: Sep-20-2024