Nhanganyaya:

Tinokugamuchirai kuSimba reHeltecblog reindasitiri! Semutungamiri muindasitiri yemhinduro dzemabhatiri e lithium, takazvipira kupa mhinduro dzakakwana dzekugadzirisa zvinhu zvese kune vagadziri vemapaketi emabhatiri nevatengesi. Tichinyanya kutarisa pakutsvagisa nekugadzira, pamwe nekugadzira zvishandiso zvemabhatiri,Simba reHeltecyakazvipira kusimbisa indasitiri iyi nekupa zvigadzirwa nemasevhisi matsva. Mushure memakore ekugadzira, michina yekushongedza mabhatiri inogara ichivandudzwa, mhando yekushongedza mabhatiri inogara ichivandudzwa. Asi tinowanzoonawo akasiyana-siyana evanobatanidza mabhatiri mufekitori imwe chete yekugadzira pamwe chete, vachiita mabasa avo. Tichabva papfungwa yemhando dzakasiyana dzemuchina wekunamira wepanzvimbokuti vanzwisise mashandiro avo.

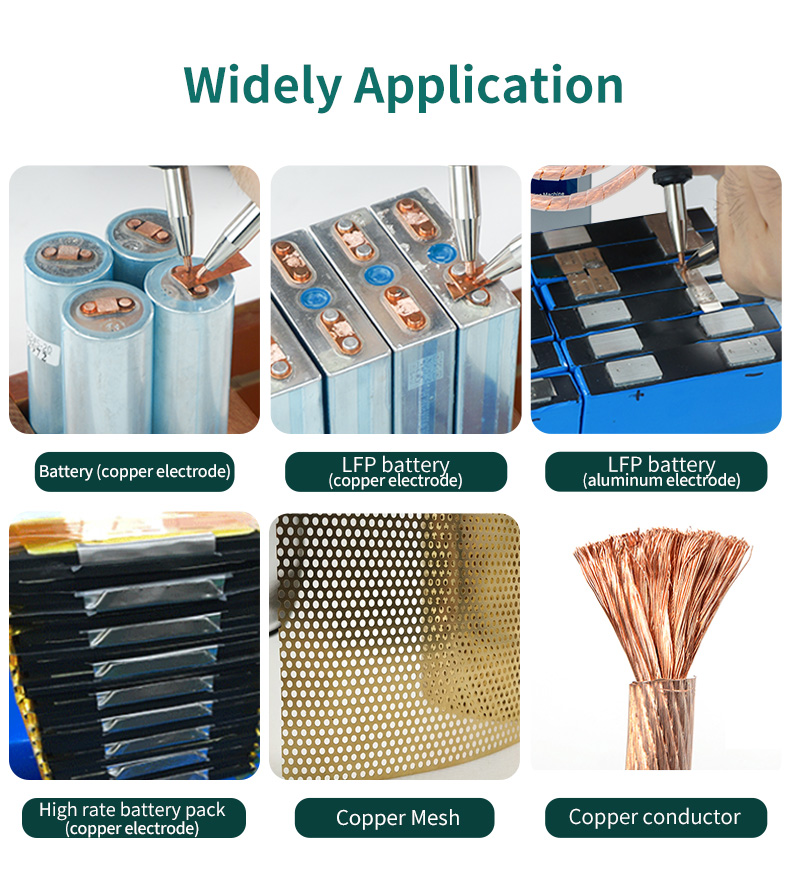

Kushandiswa:

Kupinza kwenzvimbo kunonyanya kushandiswa pakupinza kweplate thin plate. Maitiro aya anowanzo kuve ne pre-pressurization kuti zvive nechokwadi chekuti zvikamu zvebasa zvinobatana zvakanaka; electrochemistry, iyo inoumba core yakanyungudutswa ne plastic ring panzvimbo yekupinza; uye power-off forging, iyo inobvumira core yakanyungudutswa kutonhodzwa uye kusimba kana yakamanikidzwa kwenguva refu kuti igadzire agobvu, haridziki, uye harina kuputika.

Semuenzaniso, iyowelding yenzvimbo yebhatirimudziyo wakasarudzika unoshandiswa mukugadzirwa kwemabhatiri kusanganisa mabhatiri nematabhu ekubatanidza, ayo anosanganisira transformer, control system, welding tongs, cooling system, nezvimwewo. Transformer inoshandiswa kuderedza voltage yekupinda uye kuwedzera current, control system inodzora nguva yewelding uye welding current, uye inoshandisa musimboti we resistance welding kugadzira tembiricha yakakwira panzvimbo yewelding kuti iite simbi inobatanidza, nokudaro ichipedzisa welding pakati pebhatiri nechinhu chinobatanidza.

Chinhu Chedu:

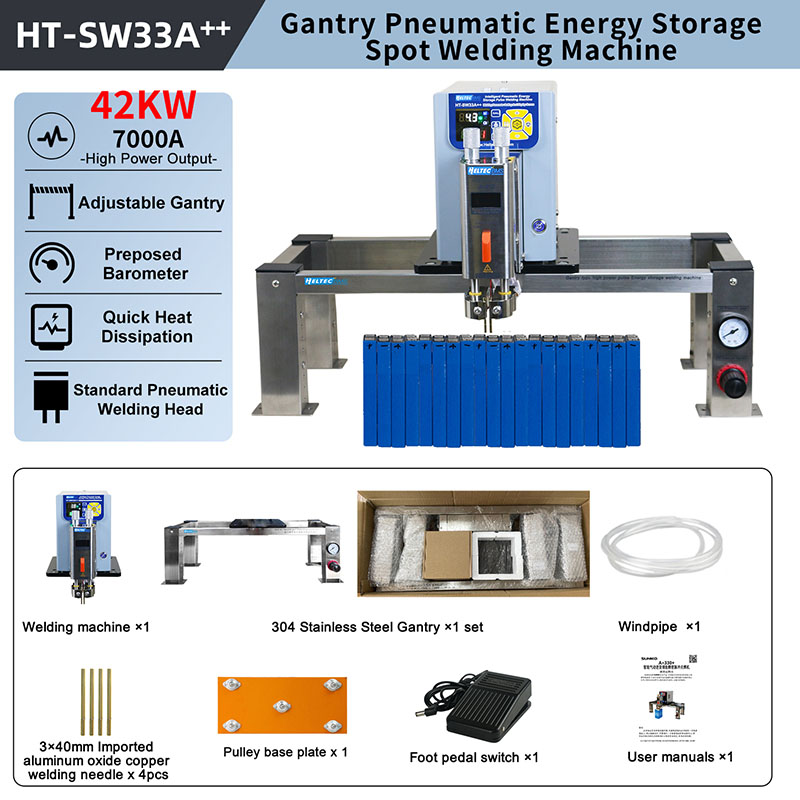

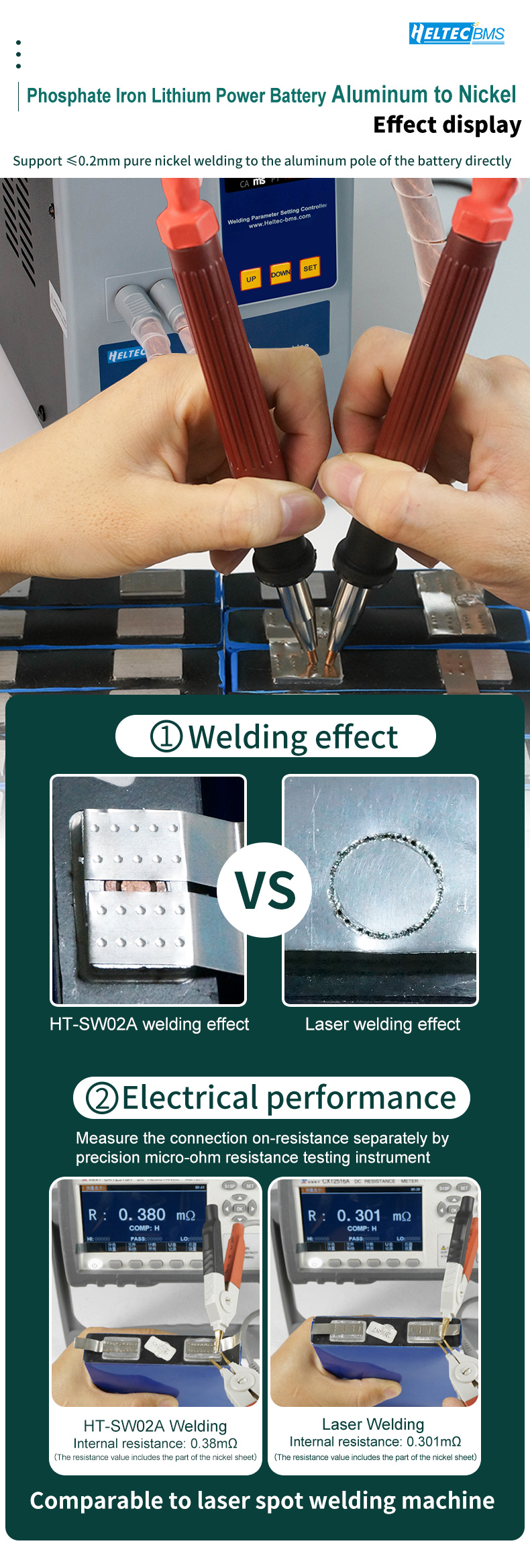

Tinonyanya kutarisa tekinoroji yepamusoro yekuwederamichina yekuwedera ine simba guruParizvino tiri nyanzvi mumichina yekuwedera ye capacitor yemagetsi yekuchengetedza simba, yakabatanidzwamichina yekuwedera yepneumatic,michina yekuchengetera nzvimbo yekuwedhesera yepneumatic yemhando yegantry, nezvimwewo. Zvichienzaniswa ne cold welding, zvigadzirwa zvedu zvine kugona kwakasimba kwe welding. Zvichienzaniswa ne laser welding tekinoroji, kunyangwe iine mabhenefiti ekushanda zvakanaka uye kunyatsoita zvinhu nemazvo, zvigadzirwa zvedu zvine mitengo yakaderera yemidziyo uye zvinodiwa zvishoma zvehunyanzvi kune vanoshanda.

Mhedziso:

Zviri pamusoro apa ndezvekutanga kwekushanda kwemuchina we welding, blog rinotevera ticharamba tichitsanangura hunhu nekushandiswa kwawo.michina yekuwedera ye capacitor yemagetsi yekuchengetedza simbauyemuchina wekunamira nzvimbo yepneumatic, ndapota tarisirai!

Kana muine mibvunzo kana kuti muchida kuziva zvakawanda, musazeza kupindurataura nesu.

Nguva yekutumira: Mbudzi-15-2023